Top 3 ways chemical industrial manufacturers extract Nitro.

In 1905, a German chemist Fritz Haber developed a new way of extracting Nitrogen (and also Hydrogen) from air, thus solving world hunger. Nitrogen could be used in the agriculture industry for creating composes – ammonia compose – that boost plants productivity, making more and more foods, grains. Later this process of Nitrogen “digging” was scaled up by an engineer and chemist Carl Bosch and named The Haber-Bosch Process. This breakthrough generated a new hope for mankind’s food issues, but also opened up a new era of the deadliest weapon during WWI: gas.

Nowaday, industries have come up with their ways of generating Nitrogen gases from the air, here are the 3 ways chemical manufacturers Malaysia do it.

Pressure Swing Absorption (PSA)

This process works based on the separation absorption of a gaseous mixture when it runs through an absorbent material. PSA operates on a 2 phase process that is happening at the same time.

Adsorption: this is the first stage where 2 towers of carbon molecular sieve adolescent material that select and absorb oxygen. This, allows the rest of the air – which is rich in nitrogen – to flow through a storage tank.

Desorption: this is the second stage where the adsorptive process of stage 1 is reversed. it, at the same time as stage 1, going through the desorption process. Trapped oxygen will be released and facilitate the renewal of the adsorptive tower for a new adsorption cycle to begin.

Resulting in a fast nitrogen-extracting method with each cycle taking only 60 seconds.

Membrane Nitrogen Generation

This method works based on the application of a semipermeable that selectively dissects the air into its constituent gas forms, which depending on the gas’s travel speed – could vary along with the speed.

Here are some of the vital components of Membrane Nitrogen Generation

Feed Filter Coalescers: this filter act as a protective layer of the obsolete membrane that prevents and stops the moisture from the compressed air to impact directly onto the membrane.

Immersion Heater Units: this heater unit plays as the heat source that penetrates the adsorptive membrane and makes sure no water or liquid passes through the filter coalescers and contact with the membranes.

Activated Carbon Filters: this filter is to ensure that any hydrocarbon vapor impurities are collected before the air enters the membranes.

Particulate Filter: this is the last step in extracting nitrogen gas through the filtering membranes. This filters out particles of 0.01 microns before the air enters the filter membranes.

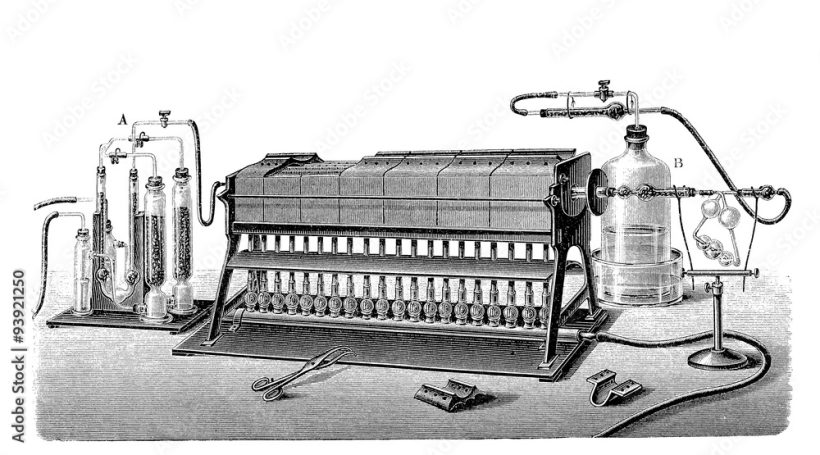

Fractional Distillation

This is the last method and is the most effective process that gives out almost purified nitrogen gas – 99,999%. Since gases like oxygen, nitrogen, carbon dioxide, and hydrogen have different melting points or liquefy points, industries will then depend on this feature.

First people will make sure the whole compound of gases is liquefied into a mixture of many liquid gases. Then they will then distill the compound by adjusting the temperature so that all of the gases except for nitrogen all vaporized. What’s left is almost pure nitrogen gas.